- Markets

- Catalogue

- Services

- Tools & Resources

- Downloads

- About Nexans

- Newsroom

-

Nexans Insights

- Nexans Insights

-

Blog Posts

- Overview

- Guide to Prevent Fires and Accidents at Home (only in Spanish)

- Ten technologies to electrify the future: Electrical and Fire Safety

- Big data & AI

- IoT

- Unveiling innovations transforming the industry

- Transforming buildings industry with 3D printing and modular construction

- The path to effective fire safety in buildings

- Powering the digital change

- Unleashing the power of DC buildings

- Sustainable buildings for a brighter future

- Industry 1, 2, 3, 4... and 5.0

- Nexans copper odyssey

- Search

- Contact us

- Compare

- Sign in

FREETOX N2XSEOHROH 3,6/6 kV; UV Resist.; for installation in vertical drilling mines

FREETOX N2XSEOHROH 3,6/6 kV; UV Resist.; for installation in vertical drilling mines

Cable for underground power distribution and subtransmission.

Read moreFREETOX N2XSEOHROH 3,6/6 kV 3x35 mm2

Nexans ref. P00038356-0

- Conductor diameter: 6.9 mm

- Diameter over Sheath: 42.4 mm

- Approximate weight: 3758 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 133 A

FREETOX N2XSEOHROH 3,6/6 kV 3x35 mm2

Nexans ref. P00038357-0

- Conductor diameter: 6.9 mm

- Diameter over Sheath: 43.7 mm

- Approximate weight: 4217 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 133 A

FREETOX N2XSEOHROH 3,6/6 kV 3x70 mm2

Nexans ref. P00016630-1

- Packaging: Cut to length (m)

- Conductor diameter: 9.8 mm

- Diameter over Sheath: 50.5 mm

- Approximate weight: 6277 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 194 A

FREETOX N2XSEOHROH 3,6/6 kV 3x95 mm2

Nexans ref. P00012260-5

- Conductor diameter: 11.5 mm

- Diameter over Sheath: 53.4 mm

- Approximate weight: 6632 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 232 A

FREETOX N2XSEOHROH 3,6/6 kV 3x70 mm2

Nexans ref. P00015491-6

- Conductor diameter: 9.8 mm

- Diameter over Sheath: 57.6 mm

- Approximate weight: 7857 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 194 A

FREETOX N2XSEOHROH 3,6/6 kV 3x95 mm2

Nexans ref. P00026473-3

- Conductor diameter: 11.5 mm

- Diameter over Sheath: 61.8 mm

- Approximate weight: 9186 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 232 A

FREETOX N2XSEOHROH 3,6/6 kV 3x120 mm2

Nexans ref. P00024187-4

- Conductor diameter: 13.0 mm

- Diameter over Sheath: 65.4 mm

- Approximate weight: 9923 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 264 A

FREETOX N2XSEOHROH 3,6/6 kV 3x95 mm2

Nexans ref. P00026397-3

- Conductor diameter: 11.5 mm

- Diameter over Sheath: 61.8 mm

- Approximate weight: 9946 kg/km

- Permissible current rating buried/duct 20°C - Trefoil formation: 232 A

Description

Description

Standards

-

InternationalIEC 60228; IEC 60332-1-2; IEC 60332-3-24 Cat.C; IEC 60502-2; IEC 60684-2; IEC 60754-1; IEC 60754-2; IEC 61034-2

-

NationalICEA S-93-639; NTP-IEC 60228; NTP-IEC 60502-2; UL 2556

Application

Power distribution in medium voltage, direct application in places with public attendance high where high mechanical strength is required, for instalation in vertical drilling mines.

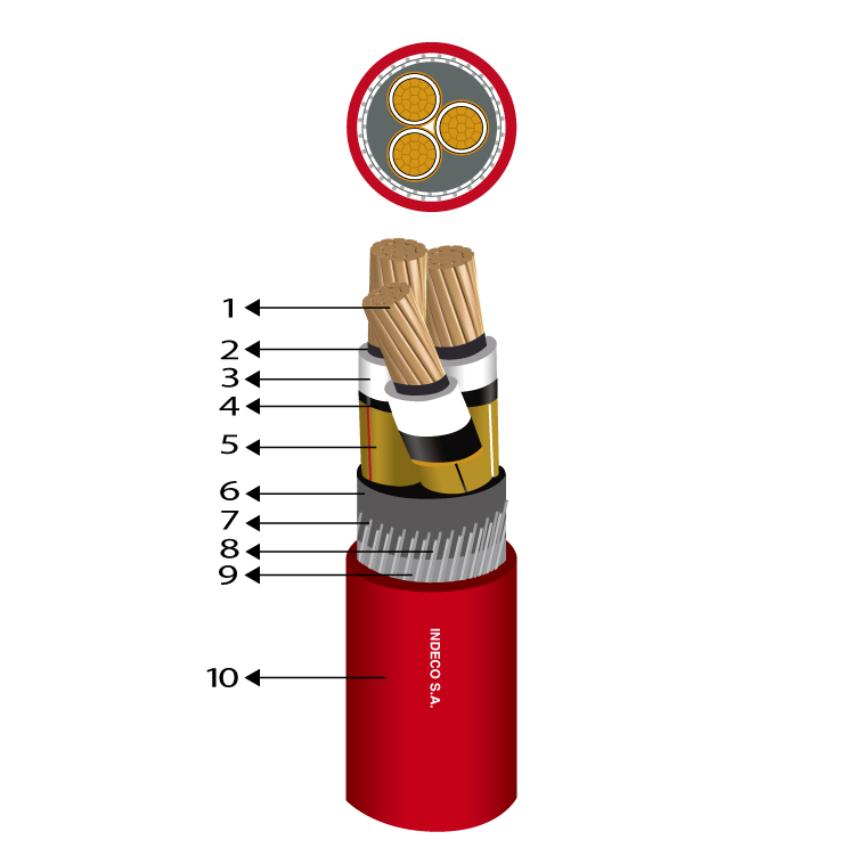

Construction

1. Conductor: Compact stranded soft copper, class 2.

2. Inner semi-conductor: Extruded.

3. Insulation: Cross linked polyethylene XLPE-TR (Tree retardant).

4. External semi-conductor: Extruded strippable.

These last three components extruded CV (continuous vulcanization) triple extrusion in dry cures process.

5. Individual screen: Copper tapes.

6. Separation sheath: Free Halogen thermoplastic compound HFFR.

7. 1st Layer armour: Galvanized steel wires.

8. 2nd Layer armour: Galvanized steel wires (when applicable).

9. Tape: Polyester.

10. Outer sheath: Free Halogen thermoplastic compound HFFR-UV.

Main characteristics

Its armour provides additional mechanical protection. The outer sheath has the following characteristics: Fire retardant, zero emission dense smoke and halogen free. Adequate resistance to oils. Sunlingth resistance.

Cross section:

From 35 mm2 up to 120 mm2.

Marking:

INDECO S.A. FREETOX N2XSEOHROH 3,6/6 kV Nb Cores x Cection - Year - Sequential length.

Packing:

Non returnable wooden reels.

Colour:

Insulation: Natural (Cores are identified with binder tapes colour: white, black, red)

Outer sheath: Red-UV.

National standards

NTP-IEC 60228: Conductors of insulated cables.

NTP-IEC 60502-2: Power cables with extruded insulation and their accessories for rated voltages from 6 kV up to 30 kV.

International standards

IEC 60228: Conductors of insulated cables.

IEC 60502-2: Power cables with extruded insulation and their accessories for rated voltages from 6 kV up to 30 kV.

IEC 60332-1-2: Test for vertical flame propagation for a single insulated wire or cable - Procedure for 1 kW pre-mixed flame.

UL 2556: Wire and Cable Test Methods. Section 9.3: FT1 (Vertical-Specimen) Flame Test.

IEC 60332-3-24: Test for vertical flame spread of vertically-mounted bunched wires or cables - Category C.

IEC 60684-2: Flexible insulating sleeving - Part 2: Methods of test.

IEC 60754-1: Test on gases evolved during combustion of materials from cables. Part 1: Determination of the halogen acid gas content.

IEC 60754-2: Test on gases evolved during combustion of materials from cables. Part 2: Determination of acidity (by pH measurement) and conductivity.

IEC 61034-2: Measurement of smoke density of cables burning under defined conditions.

ICEA S-93-639: 5-46 kV Shielded Power Cable for Use in the Transmission and Distribution of Electric Energy. Section 9.4.2: Oil Immersion Test.

UL 2556: Wire and Cable Test Methods. Section 4.2.8.5: Carbon-Arc and Xenon-Arc Tests- Sunlight resistance.

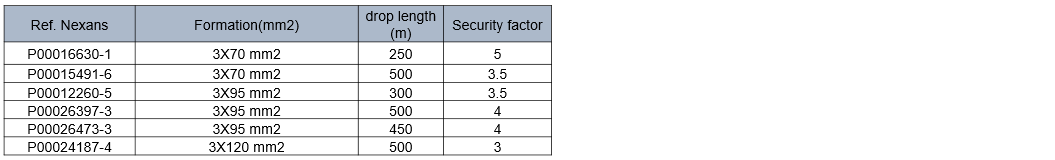

CONDITIONS FOR INSTALLATION IN MINE SHAFTS M.T.

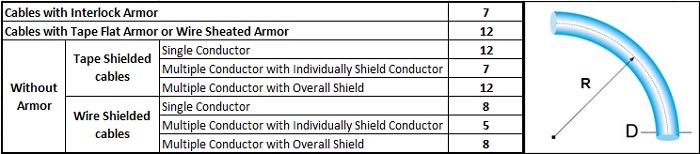

BENDING RADIUS INSTALLED IN M.V

R=Dxf

R: Bending radius when installed (mm)

D: Diameter over sheath (mm)

f: Multiplicative factor; given the following table:

Bending radius factor MV

Calculation of Current Condition Multi-core M.V.

CALCULATION OF CURRENT CONDITION BASED ON NTP-IEC 60502-2 Annex B

Maximum conductor temperature: 90°C.

Ambient air temperature: 30°C.

Ground temperature: 20°C.

Depth of laying: 0,8 m.

Thermal resistivity of soil: 1,5 K.m/W.

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania