- Markets

- Catalogue

- Services

- Tools & Resources

- Downloads

- About Nexans

- Newsroom

-

Nexans Insights

- Nexans Insights

-

Blog Posts

- Overview

- Guide to Prevent Fires and Accidents at Home (only in Spanish)

- Ten technologies to electrify the future: Electrical and Fire Safety

- Big data & AI

- IoT

- Unveiling innovations transforming the industry

- Transforming buildings industry with 3D printing and modular construction

- The path to effective fire safety in buildings

- Powering the digital change

- Unleashing the power of DC buildings

- Sustainable buildings for a brighter future

- Industry 1, 2, 3, 4... and 5.0

- Nexans copper odyssey

- Search

- Contact us

- Compare

- Sign in

CAI-S 0,6/1 kV without Public Lighting

CAI-S 0,6/1 kV without Public Lighting

For overhead secundary distribution networks.

Read moreCAI-S 0,6/1 kV 2x10mm2+P3,2mm

Nexans ref. P00024619-0-M

- Number of cores: 2

- Phase Conductor Cross Section: 10 mm²

- Phase Conductor Diameter: 3.9 mm

- Minimum insulation thickness: 1.14 mm

- Messenger conductor diameter: 3.2 mm

- Nominal outer diameter: 12.8 mm

- Approximate weight: 279 kg/km

CAI-S 0,6/1 kV 2x16 mm2+P3,2 mm

Nexans ref. P00019938-1-M

- Number of cores: 2

- Phase Conductor Cross Section: 16 mm²

- Phase Conductor Diameter: 4.9 mm

- Minimum insulation thickness: 1.14 mm

- Messenger conductor diameter: 3.2 mm

- Nominal outer diameter: 14.6 mm

- Approximate weight: 395 kg/km

CAI-S 0,6/1 kV 3x25 mm2+P3,2 mm

Nexans ref. P00024279-1-M

- Number of cores: 3

- Phase Conductor Cross Section: 25 mm²

- Phase Conductor Diameter: 6.2 mm

- Minimum insulation thickness: 1.14 mm

- Messenger conductor diameter: 3.2 mm

- Nominal outer diameter: 18.8 mm

- Approximate weight: 832 kg/km

CAI-S 0,6/1 kV 3x35 mm2+P4,8 mm

Nexans ref. P00014839-2-M

- Number of cores: 3

- Phase Conductor Cross Section: 35 mm²

- Phase Conductor Diameter: 7.3 mm

- Minimum insulation thickness: 1.14 mm

- Messenger conductor diameter: 4.8 mm

- Nominal outer diameter: 21.7 mm

- Approximate weight: 1181 kg/km

CAI-S 0,6/1 kV 3x50 mm2+P6,4 mm

Nexans ref. P00018637-1-M

- Number of cores: 3

- Phase Conductor Cross Section: 50 mm²

- Phase Conductor Diameter: 8.6 mm

- Minimum insulation thickness: 1.52 mm

- Messenger conductor diameter: 6.4 mm

- Nominal outer diameter: 26.5 mm

- Approximate weight: 1649 kg/km

CAI-S 0,6/1 kV 3x70 mm2+P6,4 mm

Nexans ref. P00014841-2-M

- Number of cores: 3

- Phase Conductor Cross Section: 70 mm²

- Phase Conductor Diameter: 10.3 mm

- Minimum insulation thickness: 1.52 mm

- Messenger conductor diameter: 6.4 mm

- Nominal outer diameter: 29.8 mm

- Approximate weight: 2252 kg/km

Description

Description

Standards

-

InternationalIEC 60228; IEC 60811-201; IEC 60811-401; IEC 60811-402; IEC 60811-501; IEC 60811-502; IEC 60811-507; IEC 60811-511

-

NationalASTM A 475; NTP 370.254; NTP-IEC 60228

Application:

For urban and rural overhead secundary distribution networks, with voltages up to 1000 V.

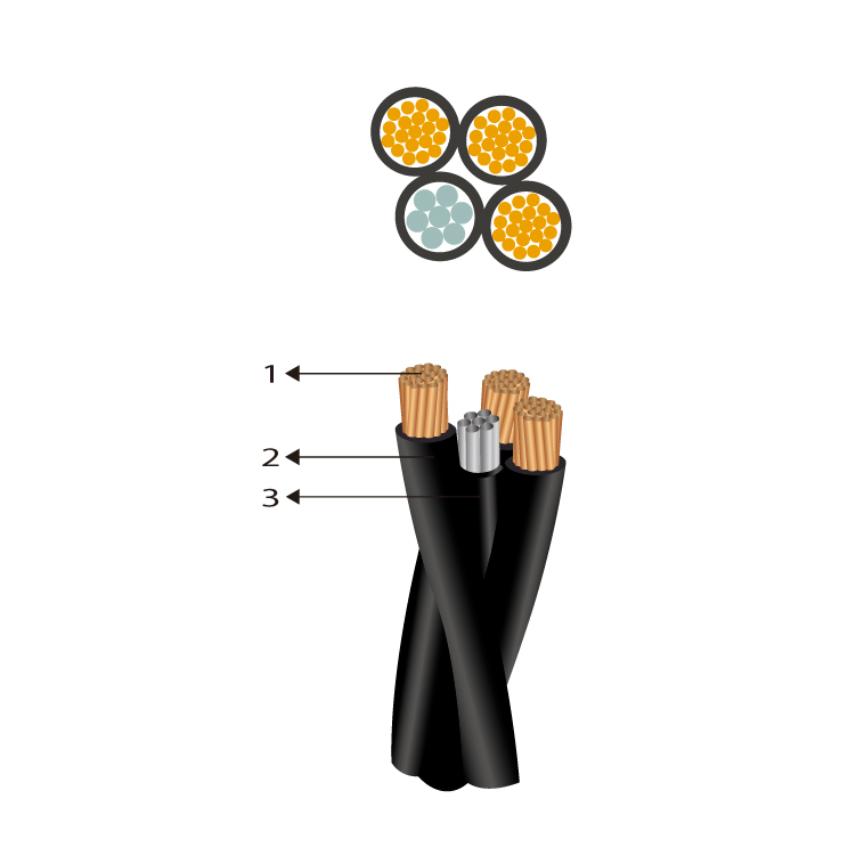

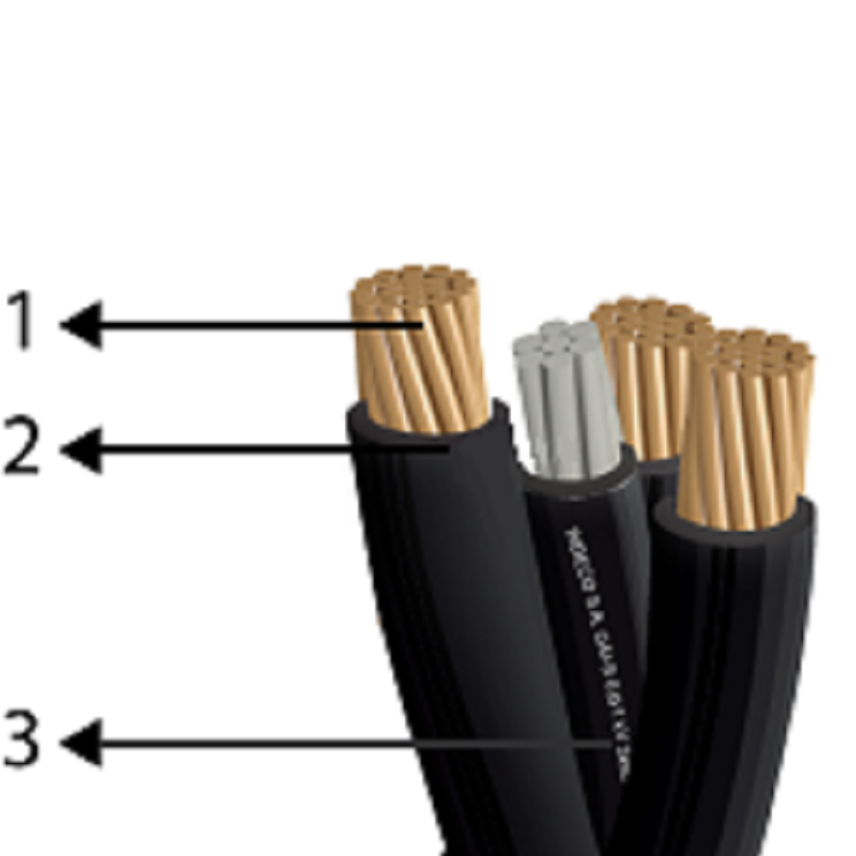

Construction:

1. Conductor: Copper, class 2.

2. Insulation: Cross linked polyethylene XLPE.

3. Insulated Messenger: Galvanized stranded steel wire - XLPE.

Main characteristics:

Increased current capacity, high insulation resistance and lower inductive reactance than with CPI conductors, higher conductivity and lower energy loss, used in overhead distribution lines. Increased safety due to its mechanical strength and toughness of the insulation. Insulators are not necessary for installation. Resistance to abrasion, weather and sunlight.

Gauge:

From 16 mm2 up to 70 mm2.

Marking:

INDECO S.A. CAI-S 0,6/1 kV - (Nb. Cores x Section) + P(Messenger diameter) - Year - Sequential length.

Packing:

Non returnable wooden reels.

Colour:

Black, see core identification.

National standards

NTP-IEC 60228: Conductors of insulated cables.

NTP 370.254: Cables for overhead distribution networks self-supporting XLPE insulated of rated voltages up to and including 0,6/1 kV.

International standards

IEC 60228: Conductors of insulated cables.

ASTM A 475: Zinc coated steel wire strand.

IEC 60811-201: Measurement of insulation thickness.

IEC 60811-401: Thermal ageing methods -Ageing in an air oven.

IEC 60811-402: Water absorption test.

IEC 60811-501: Test for determining the mechanical properties of insulating and sheating.

IEC 60811-502: Shrinkage test for isolations.

IEC 60811-507: Hot elongation test for crosslinked materials.

IEC 60811-511: Measurement of hot melt index of polyethylene compounds.

BENDING RADIUS WHEN INSTALLED

R = f x D

R: Bending radius when installed (mm).

f: Multiplicative factor.

D: Cable nominal outer diameter (mm).

Calculation of Current Condition overhead secondary distribution

CALCULATION OF CURRENT CONDITION

Maximum conductor temperature : 90°C.

Ambient air temperature : 30°C.

Speed of cross wind: 2 km/h.

Bundled conductors.

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania