- Markets

- Catalogue

- Services

- Tools & Resources

- Downloads

- About Nexans

- Newsroom

-

Nexans Insights

- Nexans Insights

-

Blog Posts

- Overview

- Guide to Prevent Fires and Accidents at Home (only in Spanish)

- Ten technologies to electrify the future: Electrical and Fire Safety

- Big data & AI

- IoT

- Unveiling innovations transforming the industry

- Transforming buildings industry with 3D printing and modular construction

- The path to effective fire safety in buildings

- Powering the digital change

- Unleashing the power of DC buildings

- Sustainable buildings for a brighter future

- Industry 1, 2, 3, 4... and 5.0

- Nexans copper odyssey

- Search

- Contact us

- Compare

- Sign in

NA2XY 0,6/1 kV 3x185 mm2

NA2XY 0,6/1 kV 3x185 mm2

General use as power cable, for fixed installations.

Read more- Nexans ref. : P00017373-1

Description

Description

Standards

-

InternationalIEC 60228; IEC 60332-1-2; IEC 60502-1; IEC 60811-401; IEC 60811-402; IEC 60811-409; IEC 60811-501; IEC 60811-502; IEC 60811-504; IEC 60811-505; IEC 60811-506; IEC 60811-507; IEC 60811-508; IEC 60811-509

-

NationalICEA S-95-658; NTP-IEC 60228; NTP-IEC 60502-1; UL 2556

Application:

General application as power cable. In low voltage distribution power networks, industrial installations, in buildings and operation stations. In fixed installations, indoor and outdoor areas (trays, gutters, staples). It can be installed in ducts, in dry or wet locations.

Construction:

1. Conductor: Compact aluminum 1350, class 2.

2. Insulation: Cross linked polyethylene XLPE.

3. Filler: Compound polyvinyl chloride PVC.

4. Outer sheath: Compound polyvinyl chloride PVC.

Main characteristics:

Good electrical and mechanical properties. Cross-linked polyethylene insulation allows greater power capacity under any operating condition, minimum dielectric losses, high insulation resistance. The PVC outer sheath allows an adequate resistance to greases, oils and abrasion. Resistance to sunlight. Flame retardant.

Cross section:

From 16 mm2 up to 185 mm2.

Marking:

INDECO S.A. NA2XY 0,6/1 kV - Nb. Cores x Section -Year - Sequential Length.

Packing:

Non returnable wooden reels.

Colour:

Insulation: See core identification.

Outer sheath: Black.

National standards

NTP-IEC 60228: Conductors of insulated cables.

NTP-IEC 60502-1: Power cables with extruded insulation and their accessories for rated voltages from 1 kV and 3 kV.

International standards

IEC 60228: Conductors of insulated cables.

IEC 60502-1: Power cables with extruded insulation and their accessories for rated voltages from 1 kV and 3 kV.

IEC 60332-1-2: Test for vertical flame propagation for a single insulated wire or cable - Procedure for 1 kW pre-mixed flame.

UL 2556: Wire and Cable Test Methods. Section 9.3:FT1 (Vertical-Specimen) Flame Test.

IEC 60811-401: Thermal ageing methods -Ageing in an air oven.

IEC 60811-402: Water absorption test.

IEC 60811-409: Mass loss test for thermoplastic insulations and covers.

IEC 60811-501: Test for determining the mechanical properties of insulating and sheating.

IEC 60811-502: Shrinkage test for isolations.

IEC 60811-504: Bending test at low temperature for insulation and covers.

IEC 60811-505: Low temperature elongation test for insulations and covers.

IEC 60811-506: Impact test at low temperature for insulations and covers.

IEC 60811-507: Hot elongation test for crosslinked materials.

IEC 60811-508: High temperature pressure tests for insulations and covers.

IEC 60811-509: Tests of resistance to cracking of the insulations and covers (thermal shock).

ICEA S-95-658: Power cables rated 2000 volts or less for the distribution of electrical energy. Section 6.4.2: Oil: Oil Immersion Test.

UL 2556: Wire and Cable Test Methods. Section 4.2.8.5:Carbon-Arc and Xenon-Arc Tests- Sunlight resistance.

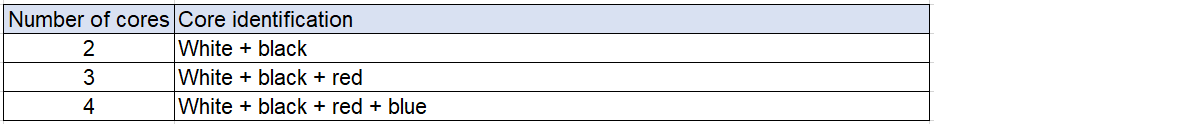

Core identification

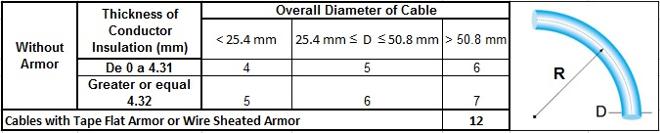

BENDING RADIUS WHEN INSTALLED IN L.V.

R=Dxf

R: Bending radius when installed (mm)

D: Diameter over sheath or over insulation (when it has not sheath) (mm)

f: Multiplicative factor; given the following table:

Bending radius factor LV

Calculation of Current Condition: Aluminum Conductor Multi-core L.V.; 90°C

CURRENT CAPACITY VALUES AND CURRENT CALCULATION CONDITIONS BASED ON IEC 60364-5-52:2009 :

TABLE B.52.5 (METHOD D1: Buried ducts in tringular formation).

TABLE B.52.5 (METHOD D2: Buried in tringular formation).

TABLE B.52.13 (METHOD E: Air in tringular formation).

Maximum conductor temperature : 90°C.

Ambient air temperature : 30°C.

Ground temperature : 20°C.

Depth of laying up to: 0,7 m.

Thermal resistivity of soil : 2,5 K.m/W.

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Mechanical characteristics

Mechanical characteristics

Usage characteristics

Usage characteristics

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania