- Markets

- Catalogue

- Services

- Tools & Resources

- Downloads

- About Nexans

- Newsroom

-

Nexans Insights

- Nexans Insights

-

Blog Posts

- Overview

- Guide to Prevent Fires and Accidents at Home (only in Spanish)

- Ten technologies to electrify the future: Electrical and Fire Safety

- Big data & AI

- IoT

- Unveiling innovations transforming the industry

- Transforming buildings industry with 3D printing and modular construction

- The path to effective fire safety in buildings

- Powering the digital change

- Unleashing the power of DC buildings

- Sustainable buildings for a brighter future

- Industry 1, 2, 3, 4... and 5.0

- Nexans copper odyssey

- Search

- Contact us

- Compare

- Sign in

RHW-2 2 kV 300 kcmil

RHW-2 2 kV 300 kcmil

Application generally in fixed installation, wet and heat resistant

Read more- Nexans ref. : P00033197-0

Description

Description

Standards

-

NationalASTM B 8; UL 2556; UL 44

Application:

Electrical system in buildings, industrial, mine and commercial. Maximum operating temperature 90°C, in dry or wet locations. Better performance than the XHHW-2 cables in harsh environments.

Construction:

1. Conductor: Compact soft copper, class B.

2. Insulation: Anti-flame cross linked polyethylene XLPE.

Main characteristics:

Offer more insulation thickness and better insulation resistance than the XHHW-2. Resistance to heat, high insulation resistance. Resistance to abrasion and moisture. Sunlight resistance. Resistant to vertical propagation of the flame VW-1. Resistant to horizontal propagation of the flame FT2. Resistant to gasoline GR II according to UL 44.

Gauge:

From 8 AWG up to 600 kcmil.

Marking:

Gauge(Section mm2) E222164(UL) RHW-2 2000 V 90°C INDECO S.A. VW-1 CT SR GR II CMPCT CU - Year - Sequential length.

Packing:

Non returnable wooden reels.

Colour:

Black.

Standards

ASTM B8: Concentric-Lay-Stranded copper conductors, hard, medium-hard, or soft.

UL 44: Thermoset-Insulated Wires and Cables.

UL 44: Thermoset-Insulated Wires and Cables. Section 5.17: Gasoline and oil resistance.

UL 2556: Wire and Cable Test Methods. Section 9.1: FT2/FH (Horizontal-Specimen) Flame Test.

UL 2556: Wire and Cable Test Methods. Section 9.4: VW1 (Vertical-Specimen) Flame Test.

UL 2556:Wire and Cable Test Methods. Section 4.2.8.5: Carbon-Arc and Xenon-Arc Tests- Sunlight resistance.

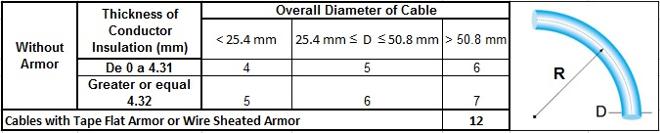

BENDING RADIUS WHEN INSTALLED IN L.V.

R=Dxf

R: Bending radius when installed (mm)

D: Diameter over sheath or over insulation (when it has not sheath) (mm)

f: Multiplicative factor; given the following table:

Bending radius factor LV

Calculation of Current Condition L.V. AWG/kcmil - Single-core 90 °C

BASED ON NEC TABLES 310.16 (IN RACEWAY) AND 310.17 (IN FREE AIR)

Maximum conductor temperature: 90°C.

For ambient temperatures other than 30°C, see tables 310.16 and 310.17, correction factors (NEC).

Characteristics

Characteristics

Construction characteristics

Construction characteristics

Dimensional characteristics

Dimensional characteristics

Electrical characteristics

Electrical characteristics

Usage characteristics

Usage characteristics

Resources

Resources

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania